Bob Carruthers’ WOOD FIRED HYDRONIC

HEATING SYSTEM - LAST MODIFIED 3/15/04

(e-mail to (Bob Carruthers) )

ROBERT CARRUTHERS

ATMOS DC 40 GS WOOD BOILER

NOVEMBER 2003

Climate 100 miles north of Seattle (mild)

House 3,800 sq ft 12’

ceilings 11 skylights (1970)

Heat demand 400 therms plus in winter Months (cascade natural

gas bill $400)

Installation paired with existing Well-McLAIN GV6 175,000 Btu

condensing gas boiler

Existing Hydronic baseboard

(165*f plus operating temp)

Plumbing 1 ¼’ cooper primary

loop the three zones being secondary loops (1 ¼”)

Gas boiler has a pair of

Taco 007F circulator pumps built in. Wood boiler has one external Taco 007F

pump. Three zones each zone has a 009F pump.

Hot water storage 500 gal (converted propane tank ¼” thick wall) R19

6” fiberglass with tin cover

Large Extrol SX series

expansion tank (see pic)

Figure 1 Heating System

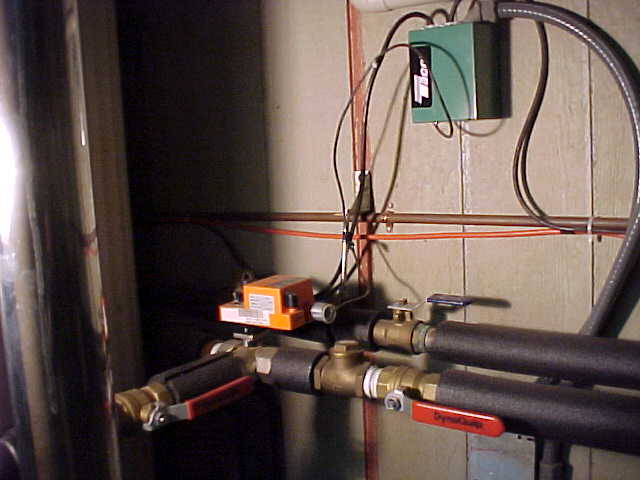

Figure 2 Self- activating

valve for cooling loop

Over heat protection for wood boiler

Self-actuating ½” valve

connected to cooling loop (Johnson V47AB4C) Normally closed. ($230)

Tripp-Lite automatic power

system 12-volt inverter charger 500 watts (car battery) ($165)

Figure 3 Backup power system

The Atmos boiler is designed

to operate at 80-90*c by way of a power regulator that controls the draft door

and an induced draft fan. At temperature the 007 circulating pump works

continuously.

System control

The system shown has an

auquastat (dp st) at the output of the wood boiler. When operating temp is

reached it locks out calls for heat to the gas boiler by opening the circuit

between house thermostats and gas boiler. It also makes a circuit to power a

relay that controls a three-way diverter valve that routes water around the

storage tank when tank temp is low (start up) giving the house priority. When

house does not call for heat the wood boiler heats the storage tank water by

way of the valve. In addition there is an aquastat (sp st) on the outlet of the

tank that locks out the diverter valve relay when the tank water is hot. The

water is then routed through the tank. These aquastats are adjustable and allow

fine-tuning. This system uses the Termovar (mixing valve) set @162*f for return

water boiler protection ($220) also used back flow check valves to prevent gas

boiler from heating storage tank water.

The system works well and

switches between boilers automatic

Figure 4 Expansion tank

Figure 5 Plumbing detail

Figure 6 Three-way diverter

valve

Figure 7 Relay and valve

Observations

When the pipe was insulated it

lowered the temp in the garage 15*f it also raised the temp of water in the

tank 10*. (195*f)

Uses average 18 cu ft of

wood per day

Opinions

Atmos boiler is the best

value I have seen it works well with dry wood and the gasification process is

easily achieved.

It will burn 3-4 hours under

heavy demand more than 6 hours average and more would be the exception.

When heat demand is not high

the gas boiler is more practical.

Heat storage

Radiant heat works better

than baseboard system as radiant demands a much lower temp than the 165*f

required for baseboard. For example I can hold 500gal at 195*f so that gives me

500gal at 30*useable before it reaches 165*f.

Radiant heat would yield 500gal at 100* of useable heat, before it

reached 90*-95*f over three times as

much as baseboard.

I think that the 500 gal tank is beneficial for efficiency but the

value of a larger tank for added heat storage would not be practical.

The tanks can be purchased

use from scrap yards ($.13 lb) ($150) Tank is easy to insulate it is supported

by a 1” rubber matt salvaged from horse trailer. Down side is cost of expansion

tank ($350)

This has been a project I

have enjoyed and am pleased with results.

Want your system posted here???

Follow this link, enter in the data you want displayed and email it to us.

Post Your Wood Fired Hydronic Web Site Visitors Form

(this is a text file, right click and save to your computer, complete this form and mail it back with your pictures)